Product Model:

The VMC1050 Vertical Machining Center is a CNC machine designed for precision machining, widely used in aluminum extrusions, metalworking, and other industrial applications. Known for its high precision, efficiency, and reliability, it is suitable for machining a wide range of complex parts.

Features

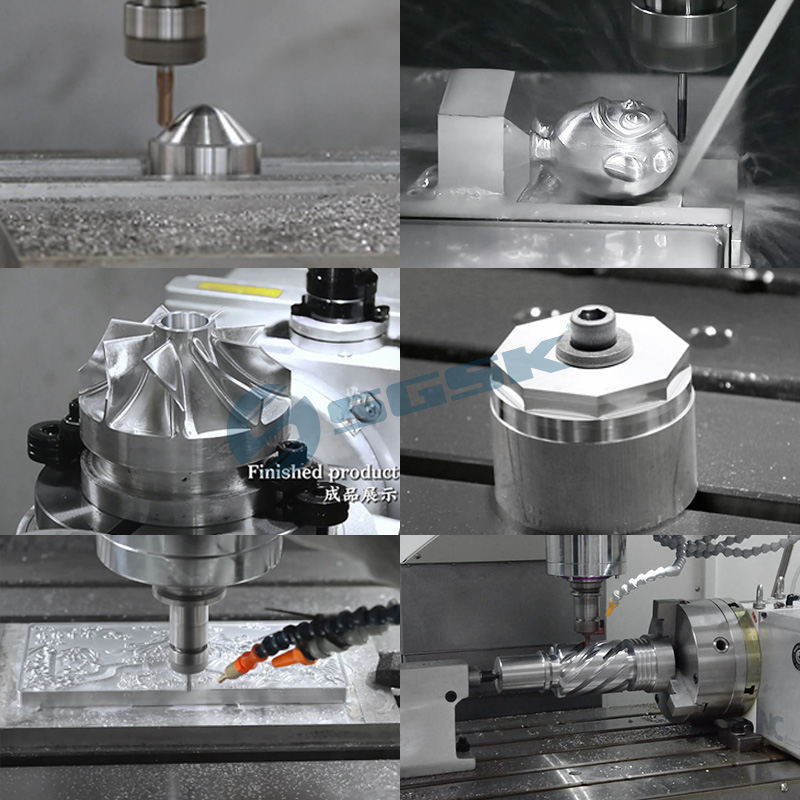

This VMC is suitable for mechanical processing and mold making .

And it can asapt to the processing requirement from rough machining to finish machining .

It can also finish many working procedures like milling ,drilling ,tapping ,boring ,etc.

1.The fuselage and main components are high strength cast iron, microstructure stability, ensure the stability of machine tool for long-term use.

2.The column at the bottom of A type bridge type structure, combined with the big box base, greatly reduce the vibration of machine on heavy cutting

3.The pre tension precision ball screw drive

4.The high speed, high precision, high rigidity spindle unit

5.The design of oil-water separation

6.The intermittent automatic lubrication

7.Automatic scraping knife system

Application

The vertical machining center can be applied to many fields such as mechanical processing and mould manufacturing, can adapt from roughing to finishing processing requirements, has the characteristics of high precision, high efficiency, is widely used in aerospace, military industry, mould, automobile, internal combustion engines, textile machinery, chemical machinery processing, oil, electronics and other industries.

Product Main Technical Parameters

Vertical Machining Center Features:

High quality resin sand

Taiwan spindle

Taiwan pressure cylinder

Taiwan linear railway

Automatic lubrication system

Chip conveyor at optional

Vertical Machining Center Application:

This VMC is suitable for mechanical processing and mold making .And it can asapt to the processing requirement from rough machining to finish machining .It can also finish many working procedures like milling ,drilling ,tapping ,boring ,etc.

Vertical Machining Center Main Technical Parameters:

| SPECIFICATIONS | Units | VMC1050 |

| Table size | mm | 1000*500 |

| X axis travel | mm | 1000 |

| Y axis travel | mm | 500 |

| Z axis travel | mm | 500 |

| Max. worktable load | kg | 500 |

| T slot(number-width*pitch) | - | 5-18*90 |

| Max. spindle speed | rpm | 8000 |

| Spindle taper | mm | BT40 |

| Main motor power | kw | 7.5 |

| X/Y/Z rapid traverse speed | m/min | 24/24/20 |

| Cutting feed speed | mm/min | 1-8000 |

| Guide rail type | - | 线轨Linear rail |

| Distance from spindle axis to column surface | mm | 525 |

| Distance between spindle nose and table surface | mm | 130-630 |

| Positioning accuracy | mm | 0.0075 |

| Repeat positioning accuracy | mm | 0.005 |

| Tool magazine | - | 圆盘Arm 24 |

| Max. tool diameter | mm | 78/120 |

| Max. tool weight | kg | 8 |

| Machine weight | kg | 5200 |

| Overall dimension(L*W*H) | mm | 3200*2400*2800 |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369